The following recommendations or ‘best-practices’ have been gathered from various industry sources in an effort to assist front-line workers in minimizing the hazards associated with ladder-use.

For the purposes of this document, the terms: ‘ladder’ or ‘ladders’ refers to ‘portable’ as opposed to ‘fixed’ devices (i.e. permanent roof-access ladders), and includes the following: Step Ladders; Platform Ladders; Extension Ladders and Step Stools.

RECOMMENDATIONS:

Only ladders bearing the CSA certification label should be used; (this assures the ladder has been manufactured to a high standard by experts in ladder construction and use).

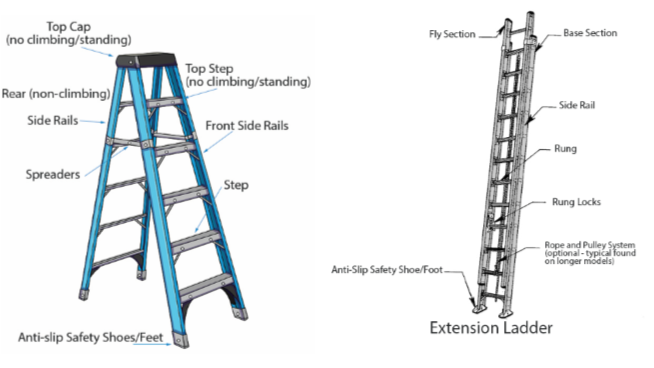

Ladders should be inspected prior to, and after every use; defects should be reported, and the ladder should be tagged and taken out-of-service. (diagrams below show components of a Step and Extension Ladder to assist with inspections)

When working near electrical services or equipment, Fiberglass (non-conductive) ladders should be used.

Ladders should only be used on a Firm, Level, Non-Slip surface free of material and debris.

Workers should keep their boots free of mud, snow, grease or other slippery materials.

When using extension ladders, workers should maintain the proper setup angle – 1 meter out for every 4 meters up (1:4 ratio). Extension sections should overlap by at least 4 rungs, and when accessing an elevated work location, the top of the ladder should extend at least 1 metre (3 rungs) above the elevated work location and should be firmly secured at the top and bottom to prevent movement.

Workers should never ‘lean or reach to one side’ – causing their center-of-gravity to affect the stability of the ladder – it is better to descend, relocate the ladder then re-ascend. The photo on the right is an example of what not to do. Not to mention, there should only be one person at a time on a ladder.

Workers should never ‘lean or reach to one side’ – causing their center-of-gravity to affect the stability of the ladder – it is better to descend, relocate the ladder then re-ascend. The photo on the right is an example of what not to do. Not to mention, there should only be one person at a time on a ladder.

Workers should always maintain 3-points of contact.

Workers should avoid excessive pulling or pushing while on a ladder – this could include the use of certain types of equipment which require using a lot of force to operate (i.e. hammer-drill).

Workers should have 2 feet on the rungs at all times while working, (this does not pertain to ascending and descending).

Ladders should only be used as means of ‘access’ and ‘egress’, as opposed to ‘work-platforms’. If a ladder is to be used as a work-platform, the employer should ensure adequate hazard identifications are performed, and be willing to provide a 2nd worker (spotter), to not only maintain stability of the ladder but also assist the worker who is performing the work. If the 2nd worker is not an option, the ladder should be tied-off to a solid object and any tools or materials required should be placed in a container and raised or lowered by rope. Further to this, if ladders are being used as work-platforms, (where the worker may be required to stand on a 4” wide tread for extended periods), accommodations should be allowed for adequate rest periods due to potential ergonomic hazards on the feet, legs, back and neck.

When not in use, ladders should be stored inside – away from extreme heat, cold or ultra-violet rays which will compromise the integrity of the material.

It only takes a second of inattention to potentially change your life forever – do not become complacent when using any type of ladder.

Download a copy of this guideline

POST Best Practices – Ladder Safety

To print, select two-sided printing and fold